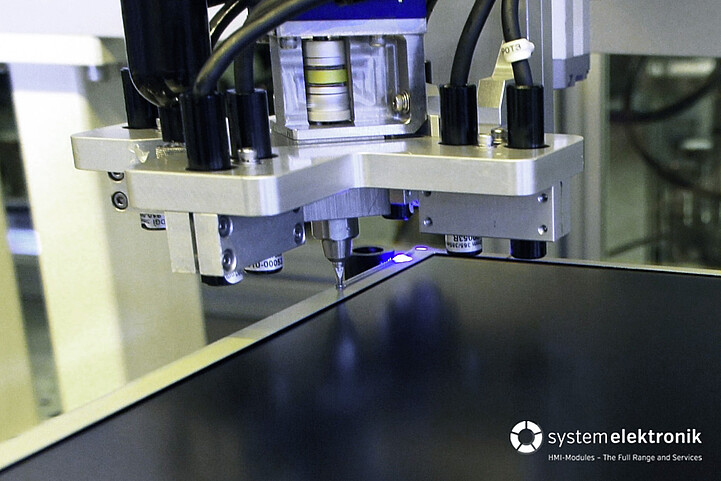

Decisive factors for good bonding include the adhesive, the repeatability in the process and the maintenance of cleanliness along the entire bonding production chain. In addition, the installation situation of the bonded assembly and the resulting influencing factors must be taken into account. Errors such as bubbles, delamination or mura, starting with the sample up to the series, are definitely avoidable. Optical bonding with liquid adhesive (Optically Clear Resin) offers decisive advantages and the required versatility. It levels out unevenness, remains permanently elastic, has strong adhesion, a low dielectric constant and offers high thermal stability. In order to meet the requirements of users, Braunschweiger system elektronik GmbH has established optical bonding processes. Depending on requirements, processes based on 1-component urethane acrylate as well as 2-component silicone are used. Bondings for TFT modules and e-paper with PCAP touch fronts as well as glass-to-glass connections in sizes from 5" to 86" are realized.

https://www.systemelektronik.de/en/optical-bonding/